Having the right accessories to complete your servo drive is essential for its correct operation and to comply with regulations such as the Electromagnetic Compatibility standards.

In this post we will talk about:

- Inductors (three-phase chokes, smoothing inductors)

- Resistors for motor braking energy dissipation

- Power-supply units capable to recover motor braking energy to mains

- EMC filters

- Transformers

If you perform retrofit works, you will probably find that some of these accessories are already in your machine cabinet. Machine electric diagrams and an inspection of the cabinet will help you understand if and what new accessories you need.

Inductors

They are divided into three categories:

- Three-phase commutation chokes: they are put between the three-phase power supply and the converter; in this way possible malfunctioning due to low line impedance can be avoided and noise due to commutation devices (SCR or IGBT) operation can be partially reduced.

- Smoothing inductors: have been designed to improve the motor armature current “form factor” when the motor inductance is low (less than 3 mH). They must be installed in series between motor and converter and can be coupled with four quadrants single and three-phase servo drives.

- Inductors for circulating current: in case a Direct Current servo drive with circulating current is used (as our “6AXD” drive), it is essential to connect two inductors, or one dual-winding inductor, to avoid damages to the servo drive and to eliminate deadzone.

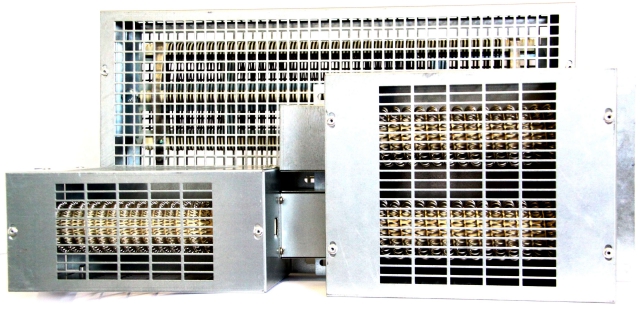

Braking resistors

Braking resistors are used to dissipate the large quantities of energy produced during braking of the electrical motor. They are available in different sizes and are coupled with ALTER servo drives when the converter internal resistor is too small and the energy recovery to mains is not possible.

Power-supply units

Stabilized power-supply units allow motor feeding and the braking energy recovery to mains. They are used when the installation of a braking resistor is not possible or not wanted. These systems, if broadly installed, allow the user to save on energy costs over time.

EMC Filters (Line filters) and shielded cables

Servo drives that use power devices like IGBTs commutate at frequencies above 10 kHz to regulate motor power supply, thus producing electromagnetic emissions, both radiated and conducted. Line filters are the key devices that are used to reduce the energy dissipated in the form of radio frequency conducted on the power supply line. Thus, EMC filters avoid malfunctioning both on control devices and in signal reception; they are also essential in order to comply with European and International standards on electromagnetic compatibility.

An old SCR Servo Drive is often replaced with a new IGBT one; since the IGBT’s commutation speed is much higher, it is essential to use shielded cables both for power cables connecting servo drive and motor, and for signal cables.

Transformers

In low-voltage Servo Drives like BTDs and DCDs made by ALTER, the converter is feed through three-phase transformers sized depending on the characteristics of the drive – motor system, on the utilization factor and, if the transformer feeds more than one motor, on the contemporaneity factor.

ALTER: the pre-sales service

During the quotation phase, ALTER Elettronica suggests the right accessories completing its servo drives and on request it can also size the transformer depending on your needs: contact us to learn more!